Sign up for our weekly email to stay on top of the latest news and insights!

Source: Sparta announcement

KENT, Wash. – Sparta Brakes have been accepted into the AMECA (Automotive Manufacturers Equipment Compliance Agency, Inc.) Police Compliance program.

Police departments and other municipalities have stringent requirements in place to ensure that these types of vehicles are safe and reliable and require minimal maintenance.

Thorough independent testing must be conducted to ensure the quality of the products meet their criteria and can provide consistent and repeatable quality and performance. In fact, the Michigan State Police and other municipalities have particularly stringent requirements that go well beyond the typical SAE criteria. Sparta products were validated and earned their Declaration of Compliance from Link Engineering in Dearborn, Mich. which developed this test.

Related post:

Sparta’s New Athena Brake Kits for Off-Road Trucks

“Sparta has the experience and capabilities to provide top quality brake components for even the most crucial vehicles like police cars.” stated Yoni Kellman, Sales and Marketing Manager. “With all of the uncertainty we are living with right now, we felt it was important to support law enforcement and our cities and neighborhoods the best way we know how, and that is by providing the highest quality brake components, at a fair price to these municipalities.”

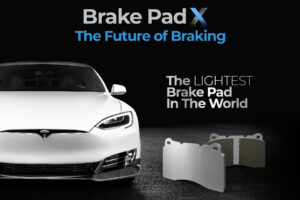

Sparta Brakes is a global entity with various tier one and tier two companies in its DNA, which contributes to the Sparta engineering advancements and quality first attitude. With brake products ranging from street and performance rotor and pad kits, to full blown oversized brake kits with two-piece floating rotors and multi-piston calipers for track days and for competition, Sparta Brakes is poised to be the next big name in high performance brake systems.

About Sparta Brakes

Founded in 2011 and headquartered in Kent, Wash., Sparta Brakes is a world class designer and manufacturer of high-performance brake systems, specifically engineered for motorsports and high-performance street applications globally. The company’s proprietary forging process enhances the quality, performance and aesthetics of its brake products.

Housed in a state-of-the-art facility, the headquarters features engineering and manufacturing capabilities that utilize the latest in CAD software and CNC machines to produce the finest quality components, from initial design to final production. The use of CAD software to run analyses like FEA, CFD and thermal analysis ensures that the braking components are as strong, lightweight and efficient as possible before going into prototyping and production. The key to the company’s success is its ability to oversee the entire process in-house, in the United States.