Sign up for our weekly email to stay on top of the latest news and insights!

Source: Graz University of Technology announcement

GRAZ, Austria — “With this test rig, we are opening up a new area of research and entering uncharted territory,” says a delighted Martin Leitner. The term “uncharted territory” was deliberately chosen by the head of the Institute of Structural Durability and Railway Technology at Graz University of Technology (TU Graz).

On the one hand, the institute will in future operate on the market as one of the world’s few independent test centers for rolling-stock braking systems.

“On average, waiting times for such approval inspections can currently be half a year to a year. We want to remedy this situation,” says Leitner. On the other hand, a major focus of the planned investigations will be on research and development projects that go beyond standard applications.

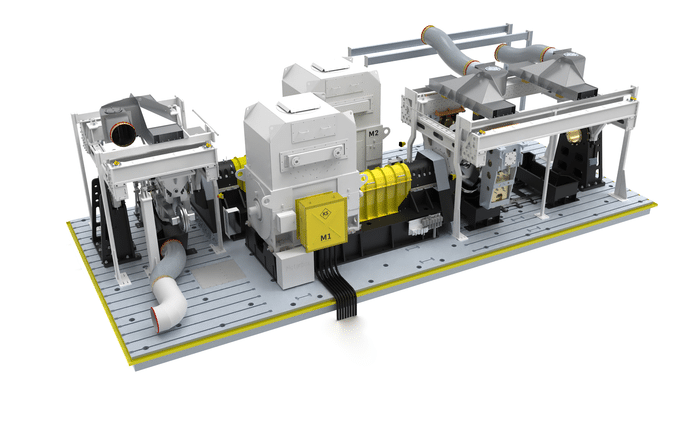

Innovative concept: electric motor instead of flywheel

Conventional test rigs of this kind work with steel discs with masses of several tons per disc, which – driven by a comparatively smaller motor – can store an enormous amount of energy. These rotating flywheel masses simulate the inertia of the rail vehicle and are braked using the brakes to be tested.

Related post:

Impact of Disabled Rail Brakes on Wheels

“The flywheel test rig is relatively inflexible and susceptible to vibrations in the drive train due to the complex mechanical structure. Furthermore, it is not possible to implement continuous braking tests until the flywheel comes to a complete standstill,” says Martin Leitner, pointing out the possible weak points.

The new brake test rig at TU Graz is based on an innovative concept. Instead of flywheels, a comparatively larger electric motor with 1.4 megawatts of power is used. This enables flexible test scenarios with rapidly changing loads to be carried out. Braking systems of high-speed trains with speeds of up to 500 km/h will also be tested.

Greater variety thanks to second test chamber

What’s more, the innovative drive system opens up a wide range of new vehicle-specific tests – from braking to a complete standstill as well as parking brake and brake jolt tests. In addition, the test rig will have two test chambers, each with its own electric machine. One test chamber is available for standard tests of individual components, such as disc or pad brakes. The second test chamber additionally fulfills special functionalities for further test scenarios with larger space requirements.

To view the entire announcement, click HERE.

Sign up for our weekly email to stay on top of the latest news and insights!