Article by: Bernat Ferrer, Project Manager, Braking Systems in Applus IDIADA

Previous Article – Part 1

Previous Article – Part 2

Previous sections have presented the methodology of this study that compares some of the most important public road brake durability standards, along with data associated with brake usage and the severity of the routes. This final part introduces the remaining brake wear and noise results.

Wear

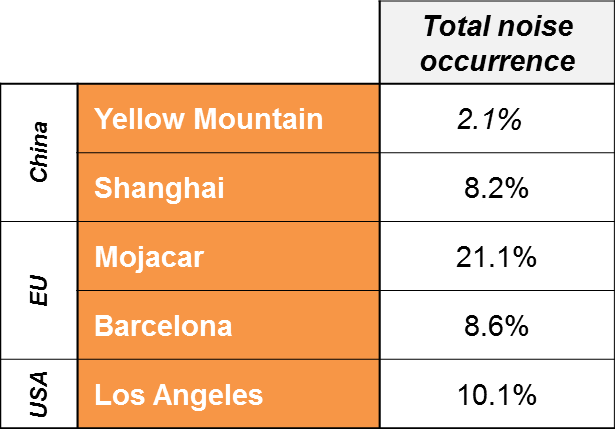

Driving style, brake actuation and specific route severity get reflected in the consumption of lining material. Wear can be evaluated in terms of volume and front/rear distribution:

Note that wear in country road profiles clearly moves towards the front axle, as the brake actuation pattern presents a higher frequency of applications at the high range of decelerations.

Brake Noise

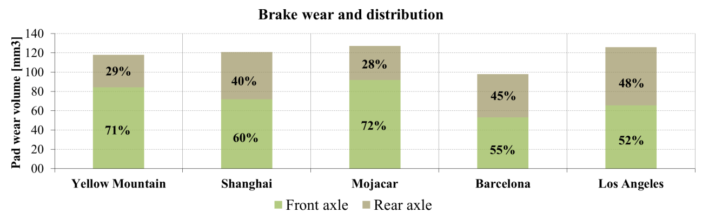

Brake noise —particularly squeal— is the final field of study:

The front axle analysis can be more robust and valuable given that less noise frequencies are found. Indeed, Mojácar is the only location where a third front squeal frequency at 9.3 kHz can be found. This is understandable given its severity in terms of wear, temperature, etc.

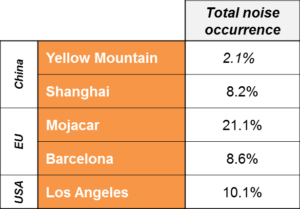

Noise occurrence can also be used as a route indicator: all city traffic profiles show very similar results (8-10% occurrence, understood as the ratio between noisy stops and the total number of brake events). Among the countryside routes, Yellow Mountain (with only 2%), clearly differs from Mojácar with 21%.

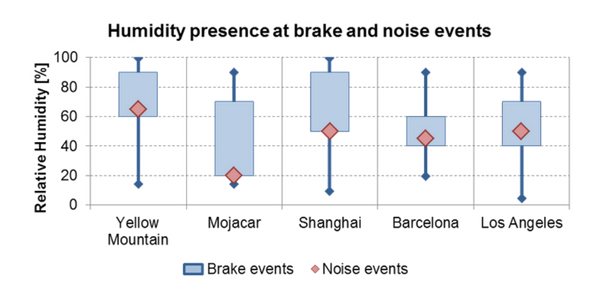

In order to understand this significant difference in occurrence, it is necessary to focus on the aspects related to the noise generation: variability of the friction material, brake usage and ambient conditions. Brake parts inconsistency between sets, carefully selected and inspected, seems to be discarded. Neither is brake usage considered: both Chinese and EU countryside profiles are very similar in terms of road distribution and severity; on the other hand, city traffic patterns present some differences with regards to brake usage, but similar values of noise occurrence. Hence, the only (and less controllable) factor remaining is the weather, and specifically humidity; although all the tests are meant to be conducted under similar ambient conditions, at some parts of the exercise this might not be achievable. Yellow Mountain is the clearest example, given that it has been performed under humid and sometimes rainy conditions. The influence of humidity on squeal generation seems to be determining:

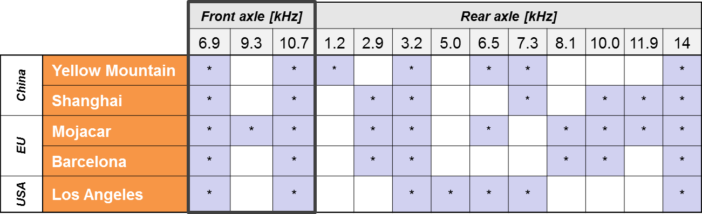

The graph above represents the relative humidity distribution at each location: the total range appearing during the durability program (marked by the vertical lines); the range where the main number of brake applications are performed (in percentile); and finally the value where most noise events are effectively generated. Overall, it seems that the trend is to get squeal noise for lower values of humidity: Mojácar is a clear example, with a wide range of humidity during the laps, but with main occurrence close to 20% level. The same situation occurs in Yellow Mountain, but in the extreme case where the humidity ranges are shifted up. Hence, for this specific friction material, humidity seems to be the most influential factor in squeal noise generation.

About Applus IDIADA

With over 25 years of experience and 2,450 engineers specializing in vehicle development, Applus IDIADA is a leading engineering company providing design, testing, engineering, and homologation services to the automotive industry worldwide.

Applus IDIADA is located in California and Michigan, with further presence in 25 other countries, mainly in Europe and Asia.